Powerful Performance in Moist Environments

Reticulated Polyether foam is incredibly versatile. Because its porousness and density can be manipulated, it offers a host of application options. But not all reticulated foam is the same. Its Polyether base determines its uses. In moist environments, our polyether foam is the ideal reticulated foam solution. This smooth, compressed, open-cell polyurethane foam, which was originally engineered for increased hydrostatic stability, can withstand continuous contact with wet materials over long periods of time. Because of its unique characteristics, it is often used for air, liquid and sound filters.

Polyether-Based Foam Key Features:

- Excellent water and humidity resistance

- Air and moisture easily flow through the cells making it an ideal filter foam

- Superior solvency characteristics

- Abrasive resistant

- Strong degradation resistance

- Cushioning properties also make it an ideal packaging material

- Can be cleaned and reused multiple times

- Mildew-Resistance

Applications

Reticulated polyether foam offers a host of uses, including:

- Humidifiers

- Ventilation Systems

- Air Conditioners

- Acoustic Foam for Speakers

- Water Purification Systems

- Fuel Tanks

- Scrubbers

- Fish/Pond Filters

- Paint Brushes

- Medical Products

- And More…

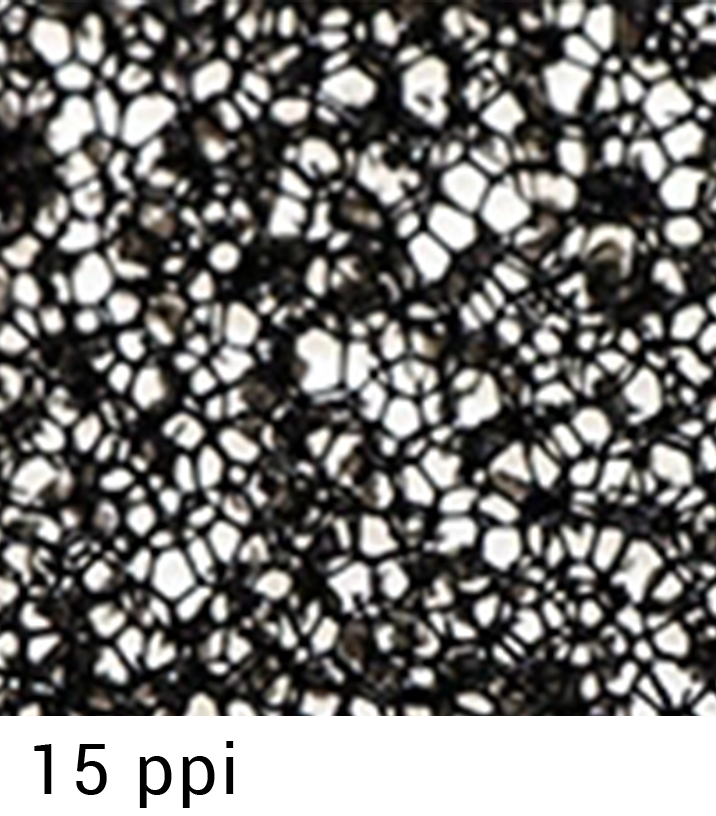

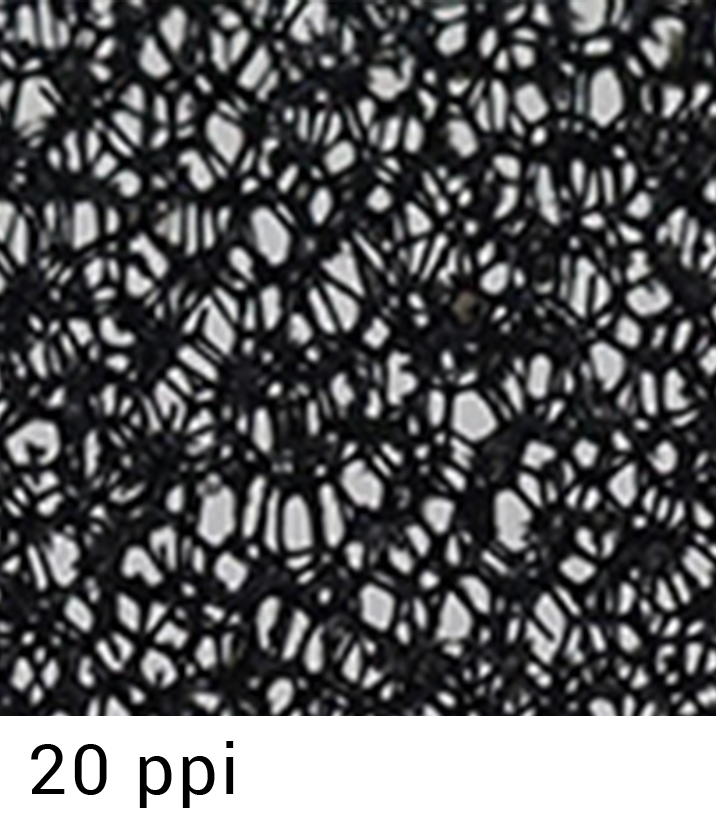

Available in a Variety of Densities and Firmness

We offer the following reticulated polyether foam ppi options:

Custom Cut for Your Needs

Our polyether reticulated filter foam is available in sheets, rolls and buns. It can be cut to any thickness up to full bun height, die cut, waterjet cut and laminated to any substrate.